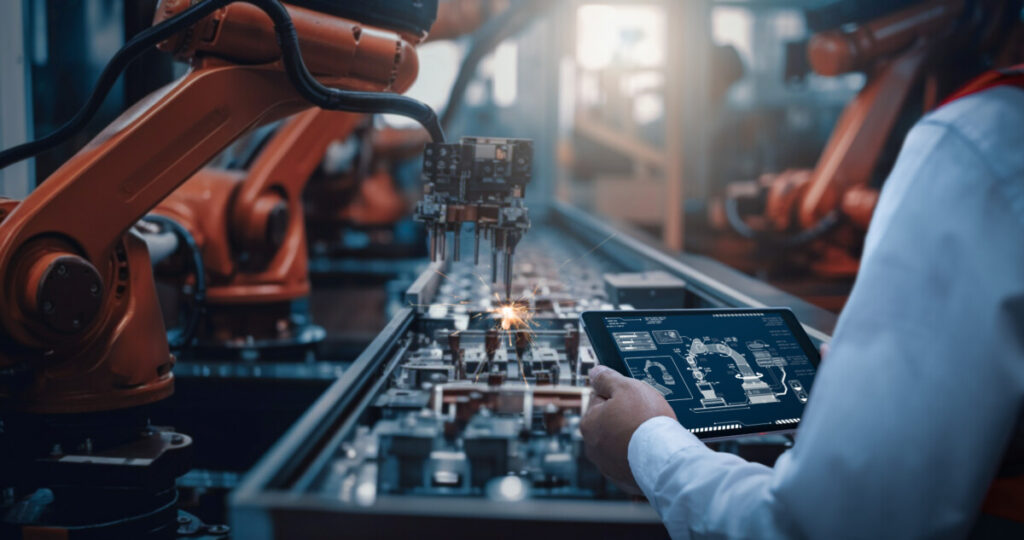

“Collaborative robotics” refers to a series of robotic arms or systems that can share a workspace with humans. These cutting-edge robots are no longer confined to a “cell” and pave the way for a different way of using robotics in industrial settings and beyond. However, cobots alone do not ensure complete safety of the operational line they are involved in.

Consider, for instance, all those tasks involving sharp or dangerous objects for the operator; one additional or uncoordinated movement could compromise the worker’s safety.

So, how can we guarantee safety in collaborative robotics?

Safety and Integration

Collaborative robots are easily used for individual production steps, isolated from the entire chain. However, through networks of dedicated sensors, operations of multiple robots can be adapted and synchronized in complex processes, potentially integrating them into PLC systems.

Moreover, to ensure safety in collaborative robotics, the programming and speed of cobots can be altered in real time. This way, their behavior is modified based on the operator’s position or the availability of objects on a conveyor belt. In the event of an improper movement or the accidental dropping of a tool, the robot can promptly stop or change direction, avoiding collisions.

What CogniMade Offers

- Position and movement detection sensors based on Infrared or Radar technology

- SIL2 certified safety sensor with Radar technology

- Gateway for integrating cobots and sensor networks into a PLC system

- Customization of Machine Vision systems based on traditional cameras and Smart Cameras

- Rental of cobot manipulators, maximum payload of 3.5Kg and 95cm reach

- Assistance with programming and integration

The advantages of a safety system for collaborative robotics

- Modern production processes

- Operational flexibility

- Cost reduction

- Reuse of robots

- Ease of programming and integration

- Increased safety and accident prevention

In conclusion, the era of collaborative robotics marks a significant step forward in industrial automation. The advantages, from greater flexibility to improved safety, demonstrate the transformative potential of these technologies. With continuous advancements in sensor technologies, collaborative robots are set to become indispensable resources in the ever-changing landscape of Industry 4.0. Embracing this revolution will undoubtedly mean for companies greater efficiency, productivity, and safety.